What Is Austenitic Stainless Steel Pipe (Tube)

Austenitic stainless steel pipes also known as austenitic stainless steel tubes, have a stable austenitic structure at normal temperatures. They contain about 18% chromium, over 8% nickel, and around 0.1% carbon. They offer excellent corrosion resistance, good cold workability, and high toughness, plasticity, weldability, and non-magnetic properties. They are widely used in heat exchangers, non-magnetic condensers, evaporators, and fluid transportation systems across industries like chemical processing, oil refining, boilers, and food production.

We specialize in manufacturing austenitic stainless steel, nickel-based alloy, duplex steel, and marine pipes. Our main materials include 304, 304L, 316L, 310S, 321/H, 347/H, 904L, 254SMo, S31803, S32205, S32750, N02200, N04400, N06600, N06625, N08800, N08825, N10276, etc. Custom materials and sizes available. We have a TS-A1 special equipment license, ISO9001, ISO14001, OHSAS18001 certifications, and EU, German, and Russian pressure equipment licenses. We are also certified by ABS, BV, CCS, DNV-GL, LR, and other classification societies. We supply quality products at competitive prices to customers in diverse industries around the world. Most of our products are exported to Europe, the US, Russia, Australia, Southeast Asia, South Africa and other regions. Feel free to contact us.

Main Grades of Our Austenitic Stainless Steel Pipe (Tube)

304 series: 304, 304L, 304H, 304LN

316 series: 316, 316L, 316H, 316LN, 316Ti

310 series: 310S, 310H

317 series: 317, 317L

347 series: 347, 347H, 347HFG

Classification of Our Austenitic Stainless Steel Pipe (Tube)

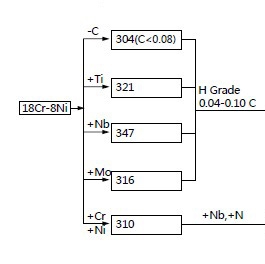

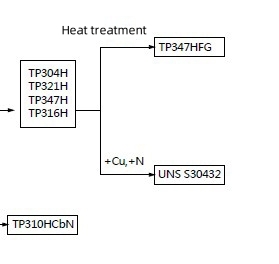

We manufacture the complete range of austenitic stainless steel pipes shown in this classification diagram. Based on 304 (18Cr-8Ni, C<0.08%), we produce enhanced variants, including: 321 (+Ti) and 347 (+Nb) for improved weldability and intergranular corrosion resistance, 316 (+Mo) for excellent chemical and corrosion resistance, and 310 (+Cr+N) for enhanced high-temperature oxidation resistance. We specialize in manufacturing these stainless steel pipes to meet diverse industrial applications.

Standards of Our Austenitic Stainless Steel Pipe (Tube)

We specialize in producing a wide range of standard austenitic stainless steel pipes such as ASTM, ASME, GB. Custom standards (EN/DIN/JIS, etc.) are available upon request.

- Key ASTM Standards

A213 – Seamless boiler tubes (heat-resistant alloys)

A249 – Welded tubes for heat exchangers/condensers

A312 – General stainless steel piping (seamless/welded)

A358 – Welded pipes for high-temperature service

A789/A790 – Duplex stainless pipes (corrosion-resistant) - ASME Standards

SA213/SA249 – Boiler & heat exchanger tubes

SA312/SA358 – Industrial process piping

SA688 – Power plant feedwater tubes

SA789/SA790 – Duplex stainless solutions - GB Standards

GB/T 5310 – High-pressure boiler tubes

GB/T 13296 – Stainless tubes for heat exchangers

GB/T 14976/12771 – Fluid transport pipes (seamless/welded)

GB/T 24593 – Welded austenitic boiler tubes

Features of Our Austenitic Stainless Steel Pipe (Tube)

- Outstanding corrosion resistance

- Excellent processing in both hot and cold conditions

- Good flexibility and toughness

- Strong overall performance

- Suitable for a wide range of applications

Application of our Austenitic Stainless steel Pipe (Tube)

We provide a wide range of products for various market needs, used in areas like water supply, drinking water, heating and cooling, food-grade piping, air compressors, fire protection, gas pipelines, and automotive systems. With excellent corrosion resistance and processing properties, our austenitic stainless steel pipes are used in a wide range of industrial applications.

1. Industrial and Agricultural Applications

Our austenitic stainless steel (201/202) pipes offer excellent acid/alkali resistance, high density, and superior mechanical and corrosion properties, making them nickel-saving alternatives. With higher room-temperature strength than 304, they maintain good oxidation resistance and medium-temperature strength up to 800°C. These pipes are mainly used in water supply and drainage systems, including industrial and residential water, wastewater, sewage, and stormwater transportation and treatment. They are also suitable for agricultural irrigation systems, fulfilling the liquid transport and water treatment needs of modern industry and agriculture.

2. Drinking Water Distribution Systems

Our 304 and 316 stainless steel pipes are widely used in direct drinking water delivery systems. Their smooth inner walls prevent scaling and help maintain water quality. With excellent corrosion and high-temperature resistance, they have a longer lifespan, better pressure capacity, and ensure safe water delivery. As they do not rust or generate secondary contamination, 304 and 316 stainless steel pipes are ideal for drinking water systems in households, hospitals, schools, and other places.

3. Urban Heating System

Austenitic stainless steel, particularly 309S and 310S, offers excellent oxidation, corrosion, and high-temperature resistance. With higher chromium and nickel content, 310S provides better creep strength, allowing it to perform continuously at high temperatures. These stainless steel pipes are widely used in various urban heating applications, such as water pipes, gas pipes, radiators, heat treatment, and heat exchangers.

4. Food and Medical Industry

304 and 316L austenitic stainless steel, used as sanitary-grade piping, offer excellent corrosion resistance and hygiene performance. These pipes are widely used in the food production and medical industries. In food production, they prevent bacterial growth, ensuring food safety and cleanliness. In the medical field, their smooth, seamless interior helps reduce bacteria and virus buildup, ensuring a sterile and safe environment.

5. Energy Pipeline Systems

Austenitic stainless steel is widely used in the energy pipeline industry for its low carbon content, excellent corrosion resistance, high-temperature resistance, and reliable connection performance. It plays a crucial role in renewable energy sources such as photovoltaics, nuclear, wind, and solar power, mainly in auxiliary exchanger tubes, feedwater heater pipes, main pipelines, and cooling water pipes.

6. Petrochemical Piping Systems

316L stainless steel, the ultra-low carbon variant of 316, delivers enhanced intergranular corrosion resistance, superior corrosion/oxidation resistance, ensuring both fluid purity and pipeline integrity. It is widely used in the petrochemical industry, especially in heating pipes, heat exchanger pipes, cooler pipes, and tower tray pipes, for transporting corrosive fluids such as acids, alkalis, and salts.

7. Automotive Industry

Austenitic stainless steels, like 304 and 316, are extensively used in the automotive industry for their excellent high-temperature and corrosion resistance. They are commonly used in exhaust systems, fuel systems, cooling systems, and other parts that require heat and corrosion resistance, providing vehicles with durability and safety across a range of conditions.

8. Aerospace application

321 and 347 stainless steels are commonly used in aerospace applications. 321 stainless steel, which includes titanium, has excellent high-temperature and oxidation resistance. 347 stainless steel, with added tantalum, provides even better high-temperature and corrosion resistance, making it suitable for aerospace structures and engine components in extreme conditions.

9. Marine engineering application

316 stainless steel is widely used in marine engineering due to its outstanding corrosion resistance, particularly for ships, offshore platforms, and subsea pipelines. 317L, which offers better corrosion resistance than 316, is well-suited for subsea pipelines and more challenging marine applications.

Latest News

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...

02 8 月 2019Copper Nickel Flanges UNS C70600Zizi offers ISO certified copper nickel flanges, stores large quantity of Cu-Ni 90/10 weld neck flan...  29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...

29 7 月 2019Stainless Steel Buttweld Fittings ManufacturerZizi is stainless steel buttweld fittings manufacturer, we offer stainless steel pipe elbow, tee, ca...  19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....

19 7 月 2019Steel Pipe Nipple Types, Dimensions and MaterialsBasic pattern of steel pipe nipple is a short piece of pipe with threads at both end or at one end....